How Quality Industrial Plumbing Can Save Your Business Money

https://epgi.com.au/wp-content/uploads/2019/08/Industrial-Plumbing.jpg 1000 667 Admin A Admin A https://secure.gravatar.com/avatar/191fafa9c1ed05bb2314052489765493?s=96&d=mm&r=gIndustrial plumbing systems are highly complex and often placed under a lot of stress when compared to residential or commercial plumbing. Brisbane, and Queensland in general, is home to some of Australia’s biggest industries, and they rely on experienced industrial plumbers to ensure they can conduct their operations without any issues.

However, not every plumbing company has the expertise to install, repair and maintain industrial plumbing. The intricacy of the networks, usage and structure require the utmost care and attention to detail.

Avoiding Costly Downtime

Any problems with industrial plumbing systems can lead to costly downtime for an organisation. Even a few hours out of action can cost large scale operations a lot of money. The best way of avoiding this is by ensuring you get experienced experts to install your industrial plumbing system and maintain and repair it.

Cost cutting by using cheaper, inexperienced plumbers to maintain your system can lead to bigger costs for your business when something goes wrong. Problems with plumbing in your industrial setting can be unpredictable and dangerous. This makes it essential to find someone who is experienced and can help you straight away if an emergency arises.

What’s Involved in Industrial Plumbing Maintenance?

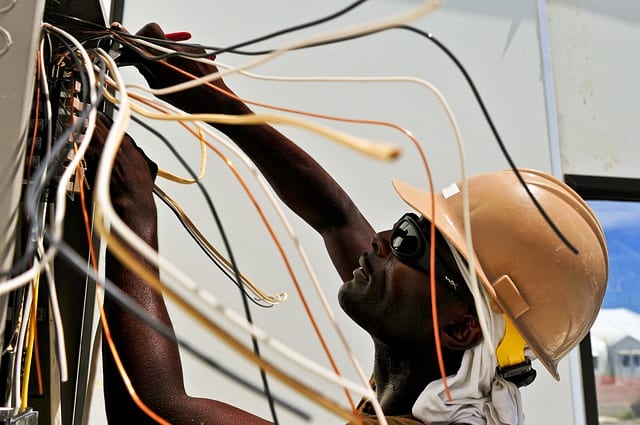

Industrial plumbers handle the installation and maintenance of heavy duty plumbing for both water and gas as well as their associated fittings. They may also take care of hot water systems, rainwater tanks and electrical systems. One of the most important maintenance jobs in an industrial plumbing system is cleaning the plumbing itself. Industrial plumbing often takes a pounding and particulates in the pipes can be what causes possible problems to occur.

Industrial Plumbing Cleaning

Cleaning industrial plumbing involve checking for and removing things inside the plumbing that may cause issues, such as:

- Particulate matter – These inevitably build up through regular use. The problem is that they take up space normally used for water, putting more pressure on your system and reducing process flow. In an intricate industrial plumbing system, this can result in anything from a busted pipe to system failure, causing serious downtime.

- Solutions – When water mixes with certain chemicals and industrial material, compounds, solids and active chemicals can form and get stuck in your pipes or damage them.

- Acidity and alkalinity – Some chemical processes are naturally acidic or alkaline. Most of these compounds get flushed out by a functioning system. They interact with anything and everything they encounter which can be trouble with an older or overworked system.

- Clogged drains and outlets – Clogged drains are a more familiar problem, but like in any plumbing system, they can cause big problems.

- Sediment – Sediments are fine particles made up of material residue. They tend to be heavy and settle in your pipes. Like particulates, they take up space, affecting water pressure and flow.

Need an Industrial Plumbing Company? Brisbane’s EPG Can Help

When it comes to industrial plumbing, Brisbane’s EPG are the experts you can rely on. Our company has extensive experience working on industrial plumbing systems and can also provide other industrial installation and maintenance services:

- Industrial electrical contractors (Brisbane wide)

- Industrial automation (Brisbane wide)

Call us on (07) 3823 1630 to discuss your requirements or contact us online.