Six Things You May Not Know About Industrial Plumbing

https://epgi.com.au/wp-content/uploads/2018/06/Order-3815-Image-10.jpg 640 480 Admin A Admin A https://secure.gravatar.com/avatar/191fafa9c1ed05bb2314052489765493?s=96&d=mm&r=gPlumbing is so much a part of daily life for most people that it’s easily ignored. Water comes out of taps, from somewhere miles away, and that’s the basic level of knowledge. That’s understandable. Most people don’t know much of the basics about plumbing, particularly plumbing on the industrial scale, which just happens to be the basis of modern life. Plumbing isn’t just “plumbing”; it’s essential to human life.

Here are a few things you may not know about industrial plumbing:

- Civilisation is Based on Plumbing

The Romans, the Indus Valley civilisation, and many others thrived because of a huge water supply system. The Roman aqueducts, still visible today around Europe, supported a huge population of millions of people which could never have otherwise functioned. Cities couldn’t have been built without the basic water supply infrastructure. Trade could never have happened on that scale without a water supply to support the big populations of the trading cities.

- Plumbing and Water Infrastructure are Essential to Societies

The basic water supply is only part of the story. Romans and other civilisations used canals, wells, pumps, dams and irrigation, all forms of basic water supply for people and agriculture. They connected their water sources to early plumbing. The Minoans, a civilisation which came and went are said to have had hot running water in the Bronze Age, as far back as 1100 B.C.

- The Industrial Revolution Created the First Modern Plumbing

Industry requires a vast amount of water for processing. From the early days of the Industrial Revolution to the present, water is a core commodity for industry. Water is used in countless chemical processes and manufacturing. Even in the mid-19th century, many people still used wells for their water supply. It was industrial plumbing, interestingly, which created modern consumer plumbing, not the other way around. By the early 20th century, the old forms of water supply were being almost totally replaced by water mains and water supply infrastructure on a global scale. The industry of commercial water supply was born.

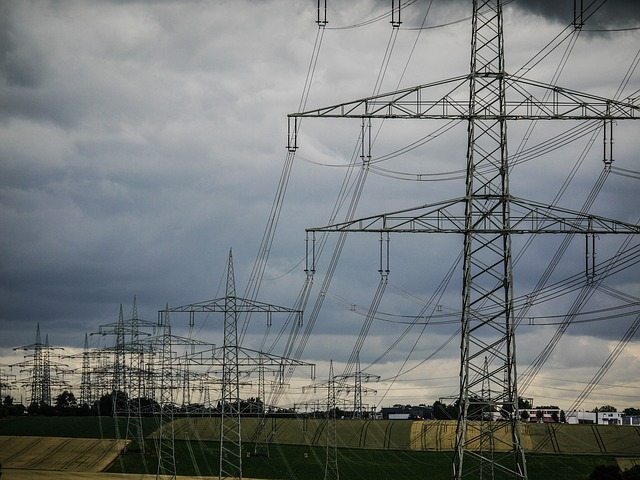

- Electricity Plus Water Supply Equals Modern Life

Electrically powered water supply systems are the current basis of water supply around the world. Water under pressure circulates through the water supply infrastructure. When a new area is opened up for human use, the water supply infrastructure is the first thing to be considered.

- Automation is Coming

Industrial automation is coming for plumbing, and it may be a huge blessing, increasing efficiencies and improving water economy. Industrial plumbers and electrical plumbing companies are now doing as much work on digital systems as on pipes and baseline plumbing. We’re not yet at the stage of Artificial Intelligence running water supplies, but the next generation of industrial plumbing will be super-efficient and very much automated, even if it does still take some guy with a spanner to make it work.

- Water quality

The other good news is that water quality is improving. New water supply systems and infrastructure are adding better filtration, backed up by monitoring to manage risks of water contamination and deliver healthy water for better quality of life.

Looking for Industrial Plumbing and Electrical Services in Brisbane?

If you’d like some industrial plumbing work done, Electrical Plumbing Group (EPG) is Brisbane’s most trusted provider of top quality services for systems, connections, new builds, infrastructure and major projects. With more than 20 years of experience, EPG not only delivers on industrial plumbing, but an understanding of our Brisbane customers. Call (07) 3823 1630 or contact us online for all the services you need.